Offset Lithography in Postage Stamp Printing: A Deep Dive into Its Process and Impact

Posted by Mystic Stamp Co. on 9th Jul 2024

Offset lithography, a printing technique that has revolutionized the production of postage stamps, combines efficiency and high-quality output. This method, which emerged in the early 20th century, has been pivotal in transforming stamp production, enabling vibrant colors and intricate designs to reach collectors and postal users worldwide.

The Basics of Offset Lithography

Offset lithography, also known as offset printing, operates on a simple yet ingenious principle. The process involves transferring an inked image from a plate to a rubber blanket, then onto the printing surface, which, in this case, is the postage stamp paper. This indirect transfer is what gives offset printing its name.

How Offset Lithography Works

- Preparation of Plates: The process begins with the creation of printing plates. These plates are typically made of metal and are treated to be hydrophilic (water-attracting) on non-image areas and hydrophobic (water-repelling) on image areas. This treatment ensures that only the image areas accept ink while the non-image areas repel it.

- Inking and Dampening: The plates are mounted on a cylinder in the printing press. As the cylinder rotates, the plate passes through a series of rollers. One set of rollers applies water to the plate, which adheres to the non-image areas. Another set applies ink, which sticks to the image areas.

- Transfer to Rubber Blanket: The inked image is then transferred from the plate to a rubber blanket cylinder. The rubber blanket, being flexible, can conform to the texture of the stamp paper, ensuring a smooth transfer of ink.

- Printing on Paper: The final step involves transferring the image from the rubber blanket to the stamp paper. This indirect method protects the plate from wear and allows for high-speed printing with consistent quality.

Advantages of Offset Lithography in Stamp Printing

Offset lithography offers several benefits that make it ideal for postage stamp production:

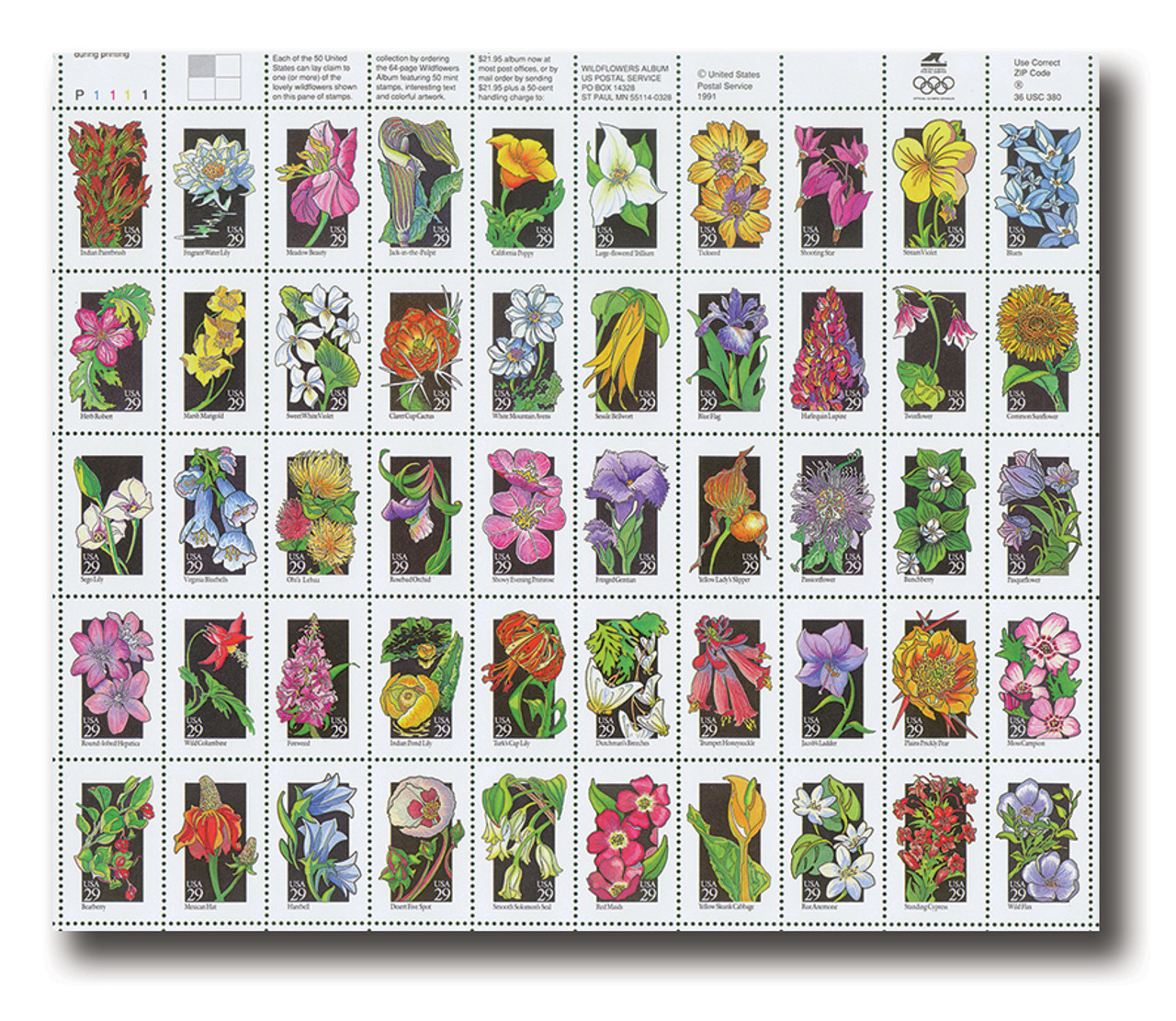

- High-Quality Images: The technique produces sharp, detailed images with a wide range of colors. This capability is crucial for stamps, which often feature intricate designs and fine details.

- Cost-Effective for Large Runs: Offset printing is highly efficient for large production runs, making it cost-effective for printing millions of stamps.

- Versatility: The process can be used on various paper types and thicknesses, allowing for flexibility in stamp design and production.

- Durability: The use of a rubber blanket minimizes wear on the printing plate, enhancing its durability and maintaining image quality over long print runs.

Historical Impact and Modern Applications

The introduction of offset lithography in postage stamp printing marked a significant technological advancement. Before its adoption, stamps were primarily printed using intaglio or letterpress methods, which, while producing high-quality prints, were time-consuming and less flexible for large-scale production.

With offset lithography, postal administrations could produce stamps more quickly and in greater quantities without compromising on quality. This efficiency was particularly beneficial during periods of high demand, such as during new stamp releases or commemorative issues.

Examples of Offset Lithography in Postage Stamps

Many countries have utilized offset lithography for their postage stamps. For instance, the United States Postal Service (USPS) has employed this method for various issues, including commemorative and definitive stamps. The vibrant colors and detailed images of stamps printed using offset lithography have made them popular among collectors and postal users alike.

Conclusion

Offset lithography has undeniably left an indelible mark on the world of postage stamp printing. Its ability to produce high-quality, cost-effective, and versatile prints has made it a preferred method for postal administrations globally. As technology continues to evolve, offset lithography remains a cornerstone of modern stamp production, ensuring that the art and utility of postage stamps continue to thrive in the digital age.