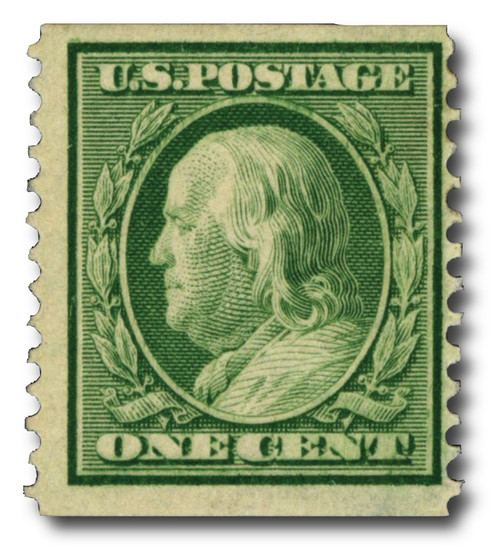

1909 1c Franklin, green, perf 12 vertical

# 352 - 1909 1c Franklin, green, perf 12 vertical

$195.00 - $1,195.00

U.S. #352

1909 1¢ Franklin Coil

1909 1¢ Franklin Coil

Issue Date: January 1909

Quantity issued: 16,656,949

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Double line

Perforation: 12 vertically

Color: Green

Quantity issued: 16,656,949

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Double line

Perforation: 12 vertically

Color: Green

On December 29, 1908, the Post Office Department ushered in a new era in both mail delivery and philately. That was the day the first coil stamps were made available at post office windows around the country. The Post Office Department had issued coil stamps once before, but only on an experimental basis, in five American cities. The experiment ended after a representative from the Post Office Department successfully “broke into” the vending machines used to sell the stamps.

The 1909 coil stamps were produced on a slightly modified version of the same flat plate press used to print sheet stamps. After the sheets were printed, they were sent through a perforating machine and perforated in only one direction. Then, the printed and perforated stamp sheets were fed into another machine that cut the sheets into twenty strips of twenty stamps each.

Because coils of only twenty stamps would not have been efficient for use in stamp vending machines, something had to be done to make the coils longer. Each of the strips had to be taken from the cutting machine by hand and glued end to end into coil rolls of either 500 or 1,000 stamps. This was the only step in the process that required manual labor. Soon, the Rotary Press would make it possible to nearly omit this step, thus automating the process almost entirely. Using the rotary press, workers only had to “paste-up” every 6,000 sheets!

U.S. #352

1909 1¢ Franklin Coil

1909 1¢ Franklin Coil

Issue Date: January 1909

Quantity issued: 16,656,949

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Double line

Perforation: 12 vertically

Color: Green

Quantity issued: 16,656,949

Printed by: Bureau of Engraving and Printing

Method: Flat plate

Watermark: Double line

Perforation: 12 vertically

Color: Green

On December 29, 1908, the Post Office Department ushered in a new era in both mail delivery and philately. That was the day the first coil stamps were made available at post office windows around the country. The Post Office Department had issued coil stamps once before, but only on an experimental basis, in five American cities. The experiment ended after a representative from the Post Office Department successfully “broke into” the vending machines used to sell the stamps.

The 1909 coil stamps were produced on a slightly modified version of the same flat plate press used to print sheet stamps. After the sheets were printed, they were sent through a perforating machine and perforated in only one direction. Then, the printed and perforated stamp sheets were fed into another machine that cut the sheets into twenty strips of twenty stamps each.

Because coils of only twenty stamps would not have been efficient for use in stamp vending machines, something had to be done to make the coils longer. Each of the strips had to be taken from the cutting machine by hand and glued end to end into coil rolls of either 500 or 1,000 stamps. This was the only step in the process that required manual labor. Soon, the Rotary Press would make it possible to nearly omit this step, thus automating the process almost entirely. Using the rotary press, workers only had to “paste-up” every 6,000 sheets!